So you’re wondering if table salt is processed?

The short answer is YES.

And here’s how it is processed..

Common Table salt refining process

Most common table salt goes through an eight step refining process:

- Brine enters a series of heaters which elevate the temperature to 290º degrees under high pressure.

- Heated supercharged brine goes into a “graveler” filled with cobblestones to remove impurities.

- Pressure is lowered via a series of “flashers,” cooling the brine to 226º degrees, allowing crystallization to begin.

- Salt crystals form in a large evaporator pan with the wet salt being automatically raked into a large well.

- This wet salt then goes into a centrifugal separator removing remaining brine.

- From there the salt then goes into a rotary dryer, making the salt perfectly dry.

- Magnetic screens are then used to separate the salt into different sizes.

- After screening, different sizes of salt are stored in their respective bins.

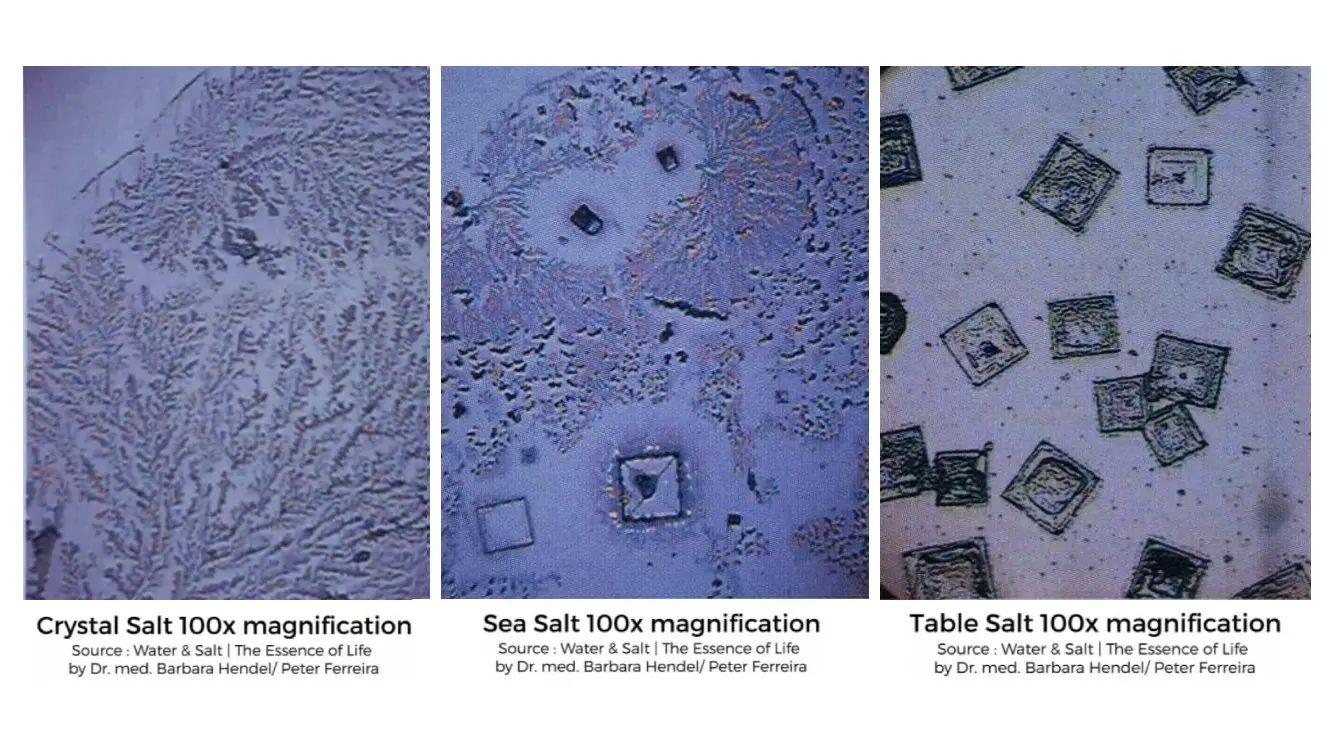

High heat processing kills the salt; removing 82 of the 84 minerals found in sea water refines the salt, and the addition of harmful additives to prevent moisture absorption and caking adulterates the salt. Regarding this last step in the making of a “junk food,” the most commonly used additives are alumino-silicate of sodium or yellow prussiate of soda. Aluminum compounds are highly toxic, having been associated with Alzheimer’s Disease and other conditions. Corn sugar (dextrose) has also been a typical additive to salt to keep it free-flowing – kind of a “double whammy” – adding sugar to your salt – just what you need!

Motivation for refining salt

It’s not too hard to see that the processing of common table salt renders it a “junk food.”

To understand the motivation, however, one need only follow the money. The primary use of salt is not as a food additive, but for industrial purposes. Only 7% of salt manufactured goes for food; the other 93% goes to industry. Industry requires chemically pure sodium chloride for manufacture of explosives, chlorine gas, soda, fertilizers and plastics. Since refined table salt is formulated specifically for industrial and chemical usage, scant concern is given to its toxic effect on human biology.

The trace minerals originally found in the salt are quite valuable. Manufacturers can sell off the trace elements found in sea water, leaving only sodium and chloride, generating a lot of extra revenue.

The resulting refined table salt still tastes salty, though like white sugar or white flour it is missing most of its original nutrients.